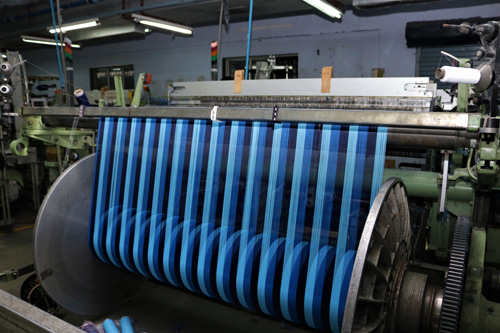

WEAVING - Dornier

We have established ourselves as coveted organization, involved in the business of trading a wide gamut of Used DORNIER RAPIER Loom.

The units are equipped with state-of-the-art Sulzer Projectiles, Picanol, Rapier and Electronic Dobby ideally located within the vicinity of Mumbai.

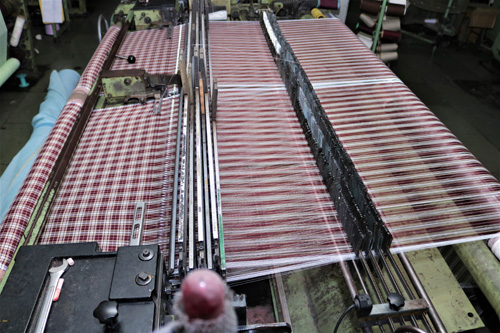

The air-jet weaving machine on the DORNIER stand offers highest economic efficiency in fashionable products.

A fashionable stretch fabric will be woven on a a 400 cm wide machine with over 2000 m/min filling insertion performance.